Installations

1. Drain Pipes

Drain pipes

Vertical drainpipes can – providing the load-bearing structure planning allows this – be inserted into the concrete chamber together with the concrete formworkelement.

Make sure the concrete is compressed. The pipes are heat insulated through the rigidfoam envelope and verywellsound insulated through the mass of the concrete. However, for revision purposes, it is always preferable to make a separate service shaft.

2. Electrical & Sanitary

Electrical/Sanitary

Electrical supply and water supply lines can be placed in all EPS formwork. The EPS is 5 cm thick and has enough space for all the lines and outlet sockets. You can selectively remove the EPS layer using standard tools; a slitting cutter, a disc sander or a hotfilament cutter.

In conventional construction the crack of the walls for electrical and sanitary installations need many time and man power. No times before the way for installations was faster and cleaner. So the client safe many construction time and naturally costs.

After inserting the lines, the plastering company can plaster the slits or they can be subsequently covered with gypsum plasterboard. After inserting the lines, you should fixate these with small plaster clamps so that the lines and outlets are seated firmly in the wall.

3. Fixing Devices

Fixing Devices

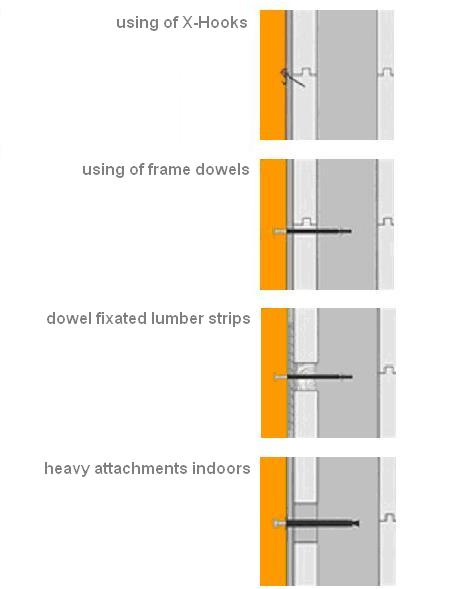

Pictures are usually fastened to MERCADO-House block walls using X-hooks. Guide these X-hooks when hammering in the nail so they can’t bend in the plaster.

For weights to be hung, up to 4 Kg, a single-nail X-hook will suffice. For weights of up to 6 Kg, it is better to use the two-nailed types and for weights up to 8 Kg the three-nailed X-hooks should be used.

Anchor large pictures, lightweight wall shelves and small wall cabinets with standard commercial frame dowels into the concrete core. One 8 x 120 mm dowel can hold a tensile pull force of 5 kN (50 Kg), 10 x 135 mm a pull of 0.8 kN (80 Kg) and 14 x 135 mm a pull of 1.2 kN (120 Kg).

As in the 5 cm thick EPS, there is a danger of buckling, the dowels should only be loaded with ca. 30 % of the weight.

For wall cupboards, stair railings, etc. it makes sense to recess the rigid foam interior insulation in the fastening area and to dowel on a 4 x 6 squared timber. All additional fixtures can be attached to this lumber strip.

Advantage: The screws will not bend. When applying the setting coat, you should lay a web in the area around the lumber strip.

Heavy attachments in the interior like washbasins, toilets, heavy wall cupboards, etc. are fastened using socalled heavy duty dowels up to the wall‘s carrying capacity. If the dowel is being loaded not only with tensile force (pull) but also with incline and transverse pull, also recess the EPS around the dowel and fill in with mounting cement. This will also prevent the screws from bending here.

Advantage: Whereas the extraction resistances in customary, thermal insulating masonry stone end at 5 kN (500 kp), the concrete core has an extraction resistance of up to 100 kN (10000 kp).

Here you can go back to the overview.

For more informations you can request here our free information package.