EPS concrete forms simplify and speed construction

Report of CCMC - the Canadian Institute for construction material test & research like BBA (U.K.) and DIBT (Germany)

The pressure to keep construction costs down means that industry is always trying to find better, faster and less expensive ways of doing things. The use of advanced technology is key in addressing these issues. CCMC facilitates the introduction of new technologies to the market by providing evaluations of these new technologies for architects and designers.

Expanded-polystyrene (EPS) forms fall into the category of "new technology" and are an alternative to conventional wood forming systems in providing a temporary structure for concrete, while it is setting and gaining sufficient strength to become self-supporting. Each EPS form consists of two insulation panels connected either by steel or plastic ties, or by the polystyrene itself. When stacked on top of each other, the forms create hollow walls, into which the concrete is poured. The variance in the connecting mechanisms creates different cores that in turn result in different wall shapes, such as post and beam, rectangular, and grid-type (see figure 1).

EPS systems provide a variety of good quality wall types, including load bearing, shear, panel and foundation or retaining walls in residential, commercial, and light industrial cast-in-place concrete construction. The systems originated in Europe approximately 25 years ago, and have captured a significant percentage of the North American construction market over the last 10 years, including in Quebec, Ontario and the West.

The popularity of EPS systems stems from their ease of use and their versatility, which can produce enormous savings in construction time and cost. They require minimal on-site equipment, because they are so light. Furthermore, they place few limitations on the creative freedom of architects, while providing better concrete hydration than conventional forming.

The evaluation conducted by IRC's Canadian Construction Materials Centre will continue to assist engineers, architects and builders in selecting (EPS) form systems that match their needs. In addition to ensuring that these modular concrete-forming systems conform with the intent of the National Building Code (1990), the evaluation also identified key areas of concern that need to be addressed by those considering their use.

The effectiveness of EPS systems depends on the forming capacity of the system; on the quality of the concrete and design analysis of the wall, and on the quality of the installation.

Fire resistance

Concrete is one of the most resistant to heat and fire. Such fire resistance gives houses built with insulating concrete forms (ICFs) certain safety advantages. Those advantages give builders and buyers yet another reason to consider using ICFs for their next project. How well do ICF walls hold up in a fire? Experience shows that concrete structures are more likely to remain standing through fire than are structures of other materials. Unlike wood, concrete does not burn. Unlike steel, it does not soften and bend. Concrete does not break down until it is exposed to thousands of degrees Fahrenheit—far more than is present in the typical house fire.

These fire ratings have been confirmed in so-called “fire-wall” tests. In these tests ICF walls were subjected to continuous gas flames and temperatures of up to 2000°F for as long as 4 hours. None of the ICF walls ever failed structurally. All of the ICFs tested were of the “flat” or “uninterrupted grid” type, having no significant breaks in the concrete layer . In contrast, wood frame walls typically collapse in an hour or less (see figure 2). Do they stop fire from spreading? Concrete walls have also proven more resistant to allowing fire to pass from one side of the wall to the other. This is especially of interest in areas with brush fires that could spread indoors.

The fire wall test confirms this rule for ICFs once again. Part of the test measured how well the wall slows the passage of heat and fire from the side with the flame to the other side. The ICF walls tested did not allow flames to pass directly through. They also did not allow enough heat through to start a fire on the cool side for 2-4 hours. In contrast, wood frame walls typically allow both flame and fire-starting heat through in an hour or less.

Will the foam add fuel to the fire? The foams in ICFs are manufactured with flame-retardant additives. These prevent the foams from burning by themselves. If you hold a match to the material, it will melt away. Of course, in a house fire, the foam may be subjected to constant flame from other materials burning nearby (wooden floors, fabrics, etc.). The “Steiner Tunnel Test” measures how much a material carries fire from an outside source. In the test, technicians line a tunnel with the material, run a fire at one end, then measure how far the flame spreads (see figure 3). The flames travel about one-fifth as far down a tunnel lined with ICF foams as they spread down a tunnel lined with wood.

Can the foam give off harmful emissions? Practically any organic material, be it wood or plastic, gives off emissions when it is subjected to intense heat or flame. The Southwest Research Institute reviewed the numerous existing studies of fire emissions and concluded that the emissions from polystyrene foams are “no more toxic” than those of wood. What precautions should I take to make my house fire resistant? No matter what your walls are made of, there is no sense playing with fire. Building codes require covering the inside face of exterior walls with a fire-resistant material, such as gypsum wallboard or a stout plaster. Using ICF walls in constructions would provide an important and effective measure of fire safety.

EPS formed concrete constructions: built-In safety

Recent laboratory testing at the Wind Engineering Research Center, Texas Tech University, compared the impact resistance of residential concrete wall construction to conventionally framed walls. The frame walls failed to stop the penetration of airborne hazards. The EPS-formed concrete walls successfully demonstrated the strength and mass to resist the impact of wind driven like hurricans.

What was tested? Various wall specimens were subjected to the impact of a 2 x 4 wood stud traveling at up to 100 miles per hour. This is equivalent to the weight and speed of an strong hurrican generated during a tornado with 250 miles per hour winds. This testing covers the maximum wind speed generated in 99 per cent of the tornadoes occurring in the United States. Wind speeds are less than 150 miles per hour in 90 per cent of tornadoes.

What's the bottom line?The strength and durability of concrete walls formed with ICFs offer unmatched resistance to the devastation of major storms. Concrete homes are less likely to suffer major damage from hurricans than conventionally framed houses. This greater measure of built-in safety makes ICF construction the quality choice for new constructions.

Comfort and quiet with EPS formed concrete buildings

Concrete walls built with insulating concrete forms effectively buffer a home’s interior from the outdoors. The thick ICF sandwich of a massive material (concrete) with a light one (foam) sharply cuts fluctuations in temperature, air infiltration, and noise. They keep the inside of a house more comfortable and quiet than ordinary wood frame walls. Where does the greater comfort come from? ICF walls increase comfort in three ways:

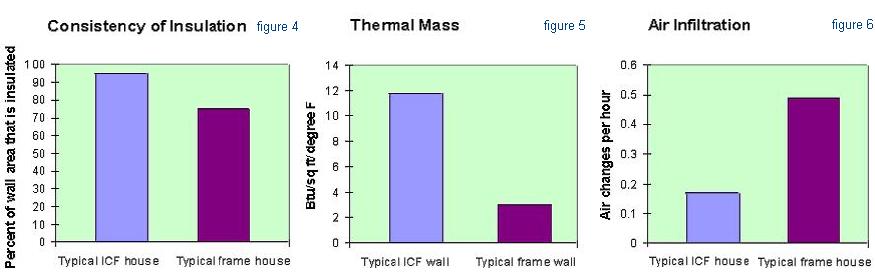

The continuous layer of foam insulation along the ICF wall helps keep the temperature the same everywhere. It virtually eliminates the “cold spots” that can occur in frame walls along the studs or at gaps in the insulation (see figure 4).

The heavy concrete of the ICF wall gives it the heat-absorbing property of “thermal mass” (see figure 5). This smoothes out swings in temperature over time. So the house does not tend to overheat or get suddenly chilly as the furnace or air conditioner cycles on and off.

The interlocking foam faces, sealed with continuous concrete in the center, make ICF walls exceptionally airtight. So drafts are cut sharply. In tests, homes built of ICFs had only about one-third to one-half as much air infiltration as the typical frame house (see figure 6).

What about noise? Massive materials like concrete tend to reflect noise.Compared to a typical wood frame wall, only about one-quarter to one-eighth as much sound penetrates through an ICF wall. Scientists would describe loud speech on the opposite side of a frame wall as "audible, but not intelligible." On the opposite side of an ICF wall, a listener would "strain to hear" loud speech. It would be virtually "inaudible." (see figure 7)

But will I really notice the difference? ICF homeowners appreciate these benefits more than they ever imagined. 1997 survey, interviewers asked owners of 74 new ICF homes and 73 new conventional frame construction homes what they liked about them. Over 80 percent of the ICF owners mentioned the great comfort, compared with 22 percent of the frame houses owners (figure 8). Typical comments were:

"It's the most comfortable house I’ve ever lived in."

"I didn’t know what I was missing until we were in it for a while."

What’s the bottom line? When planning a new building, consider the greater well-being that could come from living with a more even temperature, sharply reduced drafts, and noticeably greater quiet. These things are available with concrete walls built with ICFs. They effectively shelter the interior environment from the harshness of the outdoors. ICFs will provide a quiet, comfortable home year round.

Summary

ICFs are hollow "blocks" or "panels" made of expanded polystyrene foam (EPS) that construction crews stack into the shape of the walls of a building. The workers then fill the center with reinforced concrete to create the structure. ICF construction sandwiches a heavy, high-strength material (reinforced concrete) between two layers of a light, high-insulation one (foam). This combination creates a wall with an unusually good combination of desirable properties: air tightness, strength, sound attenuation, insulation, and mass.

Comfort: Houses built with ICF walls have a much more even temperature throughout the day and night. They have virtually no “cold spots”, and sharply fewer drafts.

Solidity: The rigidity of concrete construction reduces the flex in floors and cuts shifting and vibration from the force of the wind or the slamming of a door. Concrete houses survive high-force winds like hurricanes far better than frame constructions. And when properly reinforced, they should also withstand earthquakes well.

Quietness: About one-sixth as much sound gets through an ICF wall compared with an ordinary frame wall. This sharply cuts the intrusion of noise from outside.

Energy efficiency: The superior insulation, air tightness, and mass of the walls cut the amount of energy needed for heating and cooling by 40-70%. This can save $500-950 per year in a typical home. In addition, it allows the installation of smaller heating and cooling equipment. That can reduce the construction cost of a house by over a thousand dollars.

Design flexibility: ICF houses can be completed with almost any interior and exterior finishes and can take any shape as easily as frame constructions. In fact, some interesting effects, such as curved walls and frequent corners, can be less expensive to build into an ICF home.

Do the workers have trouble learning something so new and different?Conventional homebuilding crews adapt easily to ICF construction. Stacking blocks is intuitive for most people, and the cutting and leveling involved draw on standard carpentry skills. Most carpentry crews will have to brush up on the use of concrete, and electricians need to learn how to cut channels in the surface of the foam to house their cable. But these are not complex tasks, and there is plenty of help available.Actually, ICF construction has big advantages for the workers. The foam is light, and power equipment moves the concrete. So crews stay fresh and sharp. In fact, the simplicity of assembly and the lightness of the work help keep labor costs below those of frame construction.

....end of report

Please note, that above informations represent important parts of complete CCMC-report!

Here you can go back to the overview.